Don't miss our holiday offer - 30% OFF!

Optimizing Titanium Ore Crushing in South Africa for Superior Results

South Africa’s titanium ore processing is a vital component of its mining industry. This article explores the importance of efficient crushing plant operations, the challenges faced, and sustainable practices that contribute to the optimization of titanium ore extraction and processing.

Understanding Titanium Ore Processing

Titanium ore processing is crucial for leveraging the substantial mineral wealth of South Africa, a country endowed with significant titanium deposits. The process involves extracting titanium from its ore to be used in industries such as aerospace, electronics, and construction. South Africa’s titanium industry plays a pivotal role on the global stage, with major players like Richards Bay Minerals and Tronox leading the field. These companies employ cutting-edge crushing plants designed to maximize efficiency and output.

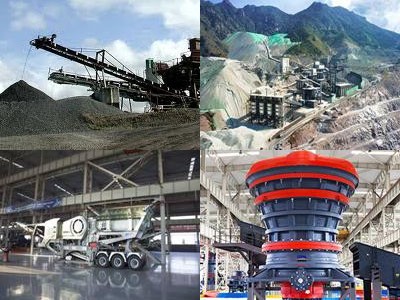

Crushing plants are essential in transforming raw titanium ore into usable materials. They reduce large rocks into smaller, more manageable pieces, facilitating further processing stages. This is where Zenith’s advanced machinery comes into play. Their range of crushers, including the C6X and PEW Jaw Crushers, HPT Cone Crusher, and VSI6X Sand Crusher, among others, are integral to optimizing the crushing process. These machines are known for their durability, efficiency, and ability to handle the rigorous demands of titanium ore processing.

The importance of titanium in the global market cannot be overstated. Its lightweight, strong, and corrosion-resistant properties make it indispensable in aerospace for manufacturing aircraft parts, while its non-reactive nature suits it for medical implants and electronics. As demand grows, efficient and sustainable processing becomes increasingly vital, underscoring the significance of South Africa’s crushing plants in meeting global needs.

Challenges in South Africa’s Titanium Crushing Plants

In South Africa, titanium ore crushing plants face several challenges that impact both efficiency and sustainability. One key issue is the variability of ore grades, which can significantly affect the consistency and quality of the output. This inconsistency necessitates frequent adjustments in processing techniques, which can lead to increased operational costs and reduced productivity. Infrastructural limitations also pose significant challenges, as many plants struggle with outdated equipment and insufficient capacity to handle the growing demand for titanium.

Environmental concerns are another major challenge. South Africa’s rich biodiversity requires mining operations to adhere to stringent environmental regulations. This includes managing dust emissions and water usage, which are critical in maintaining ecological balance. The adoption of advanced technologies, such as the Zenith C6X Jaw Crusher and HPT Cone Crusher, is vital in addressing these challenges. These machines are designed to handle varying ore grades efficiently while minimizing environmental impact.

Ensuring the safety and health of workers is paramount. By integrating technologies like real-time monitoring systems, plants can improve safety protocols and reduce the risk of accidents. Embracing innovative solutions not only enhances operational efficiency but also aligns with sustainable and responsible mining practices, reinforcing South Africa’s role in the global titanium market.

Advanced Technologies Enhancing Ore Crushing Efficiency

In South Africa, advancements in technology have revolutionized titanium ore crushing, significantly enhancing efficiency and sustainability. Automated machinery, such as the Zenith C6X Jaw Crusher and the HPT Cone Crusher, has become pivotal. Their adaptive designs reduce energy consumption and maintenance costs, addressing previous infrastructural constraints. Real-time monitoring systems integrated with crushers like the CI5X Impact Crusher allow operators to quickly adjust to variable ore grades, minimizing downtime and maximizing throughput. Further optimization is achieved with intelligent systems like the VSI6X Sand Crusher, which fine-tunes operations through predictive analytics and machine learning.

Case studies highlight the profound impacts of these technologies. For instance, the implementation of the K3 Portable Crushing Plant in a prominent South African facility led to a 20% increase in output efficiency and a 15% reduction in operational costs. Similarly, the deployment of the PFW Impact Crusher in another plant facilitated rapid adjustments to the ore’s variable characteristics, greatly enhancing reliability. These innovations not only improve economic viability but also support the broader vision of sustainable mining by decreasing energy usage and minimizing waste in titanium ore processing.

Sustainability Practices in Titanium Ore Processing

Sustainability is a key focus in South Africa’s titanium ore processing plants, with efforts concentrated on minimizing environmental impact while maintaining operational efficiency. One of the most impactful practices is water recycling. Given the high water demand in ore crushing and processing, plants have implemented closed-loop systems that treat and reuse process water multiple times. This reduces dependence on local water sources, a critical initiative in water-scarce regions of South Africa.

Another noteworthy measure is the reduction of greenhouse gas emissions through energy-efficient machinery and renewable energy integration. Equipment such as the Zenith C6X Jaw Crusher and HPT Cone Crusher are designed with energy efficiency in mind, consuming less power while delivering superior crushing capacity. Some plants are also incorporating solar energy and hybrid power systems to offset reliance on fossil fuels.

Effective waste management strategies are also being prioritized. Tailings, a major byproduct of ore processing, are now being repurposed where possible. For example, some plants use advanced crushing solutions like the Zenith VSI6X Sand Crusher to process waste material into construction-grade aggregates, reducing landfill disposal.

Corporate responsibility programs further enhance sustainability by supporting local communities. Mining companies fund initiatives such as skills training, infrastructure development, and environmental education, ensuring that communities benefit from mining activities beyond job creation. These combined efforts demonstrate how South African titanium ore processing plants are redefining operational sustainability.

Conclusions

Optimizing titanium ore crushing plants in South Africa requires understanding the complex processes and challenges involved. Employing advanced technologies and sustainable practices improves efficiency while reducing environmental impact. As the global demand for titanium rises, these practices are crucial for maintaining South Africa’s leading position in the market.