Don't miss our holiday offer - 30% OFF!

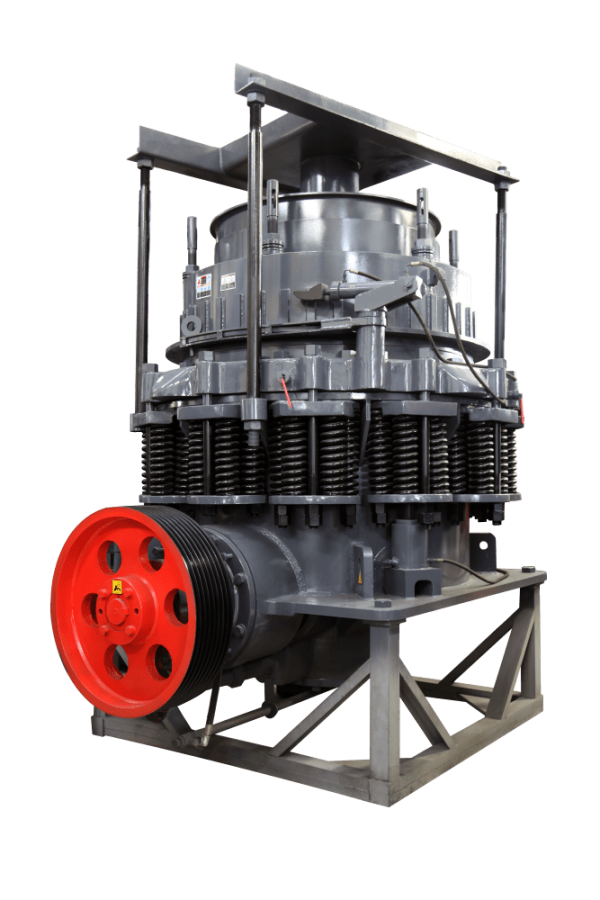

S Spring Cone Crusher

Inheritance of classic design, innovation of technological research and development, achieving stable and efficient performance

The S Spring Cone Crusher is developed by ZENITH based on the introduction and absorption of foreign technology. According to the customers’ requirement and based on the laminating crushing principle and concept of more crushing and less grinding, S Spring Cone Crusher is designed and developed as a modern high-performance spring cone crusher integrating high swing frequency, optimized cavity type and reasonable stroke.

Materials:Granite, diabase, basalt, river pebble, limestone, dolomite, metal ore and non-metallic ore

Product Advantages

S Spring Cone Crusher retains the classical structure to a great extent, and the reliability under various operating conditions is greatly guaranteed.

S Spring Cone Crusher has two types of standard version and short-head version. Each type has various cavities to satisfy materials with different hardness and different requirements.

S Cone Crusher crushes materials based on lamination crushing principle. Finished materials are cubical with high content of fine grains, suitable for high-quality aggregate production.

S Cone Crusher is equipped with a hydraulic lubrication system, which makes discharging adjustment and cavity cleaning get easier.

Working Principle of S Spring Cone Crusher

When an S Cone Crusher is working, motor drives eccentric bush rolling through triangular belt, big pulley, transmission shaft, bevel pinion and big bevel gear. The main shaft is swinging under the force of eccentric bush to make the mantle sometimes close to and sometimes far from the concave, thus making the materials be impacted, extruded and bended constantly in the annular cavity between fixed cone and movable cone and then be crushed. After impacting, extruding and bending for many times, materials are crushed to the required particle size and discharged from discharging port.

Parameters

| Model | Movable Cone Diametermm (inch) | Chamber Style | Opening Side | Closed Side | Discharging Opening (mm) | REV (r/min) | Power (kW) | Capacity (t/h) | Machine Size (mm) |

| Max.Feeding (mm) | |||||||||

| 36(3′) | 900 (3′) | fine | 83 | 102 | 9-22 | 580 | 75 | 45-91 | 2821×1880 ×2164 |

| coarse | 159 | 175 | 13-38 | 59-163 | |||||

| 36(3′) | 900 (3′) | fine | 13 | 41 | 3-13 | 580 | 75 | 27-90 | 2821×1880 ×2410 |

| medium | 33 | 60 | 3-16 | 27-100 | |||||

| coarse | 51 | 76 | 6-19 | 65-140 | |||||

| 51(4.25′) | 1295 (4 1/4′) | fine | 109 | 137 | 13-31 | 485 | 185 | 109-181 | 2800×2342 ×2668 |

| medium | 188 | 210 | 16-31 | 132-253 | |||||

| coarse | 216 | 241 | 19-51 | 172-349 | |||||

| 51(4.25′) | 1295 (4 1/4′) | fine | 29 | 64 | 3-16 | 485 | 160 | 36-163 | 2800×2342 ×2668 |

| medium | 54 | 89 | 6-16 | 82-163 | |||||

| coarse | 70 | 105 | 10-25 | 109-227 | |||||

| 66(5.5′) | 1650 (5 1/2′) | fine | 188 | 209 | 16-38 | 485 | 240 | 181-327 | 3911×2870 ×3771 |

| medium | 213 | 241 | 22-51 | 258-417 | |||||

| coarse | 241 | 268 | 25-64 | 299-635 | |||||

| 66(5.5′) | 1650 (5 1/2′) | fine | 35 | 70 | 5-13 | 485 | 240 | 90-209 | 3917×2870 ×3771 |

| medium | 54 | 89 | 6-19 | 136-281 | |||||

| coarse | 98 | 133 | 10-25 | 190-336 | |||||

| 84(7′) | 2134 (7′) | fine | 253 | 278 | 19-38 | 435 | 400 | 381-726 | 5200×4300 ×4700 |

| medium | 303 | 334 | 25-51 | 608-998 | |||||

| coarse | 334 | 369 | 31-64 | 870-1400 | |||||

| 84(7′) | 2134 (7′) | fine | 51 | 105 | 5-16 | 435 | 400 | 190-408 | 5200×4300 ×4700 |

| medium | 95 | 133 | 10-19 | 354-508 | |||||

| coarse | 127 | 178 | 13-25 | 454-599 | |||||