Don't miss our holiday offer - 30% OFF!

What Are The Features Of A Jaw Crusher 150 X 250?

As one of the fundamental machines used in the mining and construction industries, the jaw crusher 150 x 250 plays a crucial role in processing various materials. Manufactured by reputable companies like Zenith, this equipment embodies precision engineering and robust construction to withstand the rigors of demanding applications. In this article, we delve into the features and functionalities that make the jaw crusher 150 x 250 a standout choice for crushing operations.

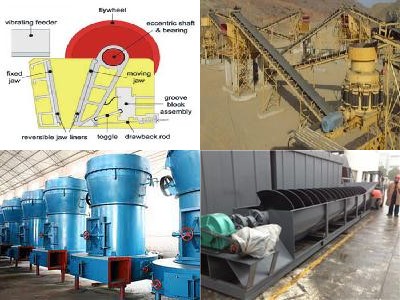

Key Components and Working Mechanism

The jaw crusher 150 x 250 comprises several essential components meticulously engineered to ensure optimal performance. At its core lies the sturdy frame, crafted from high-grade materials to provide structural integrity and support the crushing chamber. Within the chamber, the primary crushing action is facilitated by the oscillating motion of the movable jaw against the fixed jaw, powered by a reliable motor. Additionally, Zenith’s jaw crusher 150 x 250 incorporates a versatile adjustable discharge opening mechanism, allowing operators to regulate the size of the crushed material with precision.

Notable Features and Advantages

Zenith’s jaw crusher 150 x 250 boasts a plethora of features designed to enhance productivity and efficiency on the job site. One standout feature is its user-friendly design, which simplifies maintenance procedures and reduces downtime. Furthermore, this equipment is equipped with advanced safety features to protect operators during operation. Its compact size and maneuverability make it suitable for both stationary and mobile crushing applications, offering versatility across various industries. Additionally, the jaw crusher 150 x 250 delivers consistent performance even when handling challenging materials, ensuring reliable operation in diverse working conditions.

Applications and Considerations

The jaw crusher 150 x 250 finds widespread applications across industries such as mining, construction, and demolition. Its ability to crush different types of materials, ranging from hard and abrasive to soft and sticky, makes it a versatile solution for primary crushing tasks. Whether processing aggregates, minerals, or recycled materials, this equipment excels in delivering high-quality end products. However, potential buyers should consider factors such as feed size, throughput capacity, and required particle size distribution when selecting the jaw crusher 150 x 250 for their specific applications.

In conclusion, the jaw crusher 150 x 250 offered by Zenith exemplifies excellence in design, performance, and reliability. With its robust construction, innovative features, and broad range of applications, this equipment is a valuable asset for any operation requiring efficient primary crushing. To complement your crushing needs, Zenith also offers a comprehensive range of related products, including mills, screens, and conveyors, designed to work seamlessly with the jaw crusher 150 x 250 for a complete crushing solution. Trust Zenith for all your crushing and screening requirements, and experience unparalleled efficiency and productivity in your operations.