Don't miss our holiday offer - 30% OFF!

What Equipment Do You Need For A Crusher Quarry?

In the demanding world of quarry operations, having the right equipment is crucial for efficiency, safety, and profitability. This article will guide you through the essential machinery, key features, and supporting tools necessary for a successful crusher quarry operation. As a leading provider of industrial solutions, Zenith company offers a range of top-tier crusher quarry equipment designed to meet the rigorous demands of the industry.

Essential Machinery for a Crusher Quarry Operation

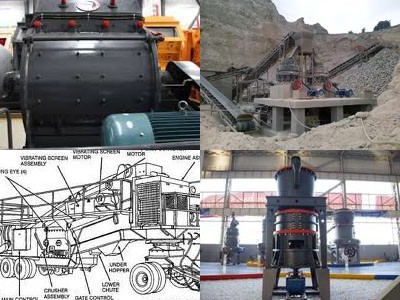

The backbone of any crusher quarry is its heavy-duty machinery. Primary crushers, such as jaw crushers, are indispensable for breaking down large boulders into manageable sizes. Cone crushers follow, providing fine crushing to achieve the desired granularity. Impact crushers are also vital, used for their efficiency in producing specific shapes and sizes. Zenith offers robust models of each type, ensuring optimal performance and durability.

In addition to primary crushers, screening equipment is essential for sorting materials by size and facilitating efficient workflow. Vibratory screens and rotating trommels are common choices. Conveyors, too, play a critical role in transporting materials between different stages of the crushing and screening process. Zenith’s high-capacity conveyors are engineered for seamless integration and minimal downtime.

Lastly, feeders are crucial for regulating the flow of materials into crushers, preventing jams and promoting a smooth operational flow. Zenith provides a variety of feeders that can be tailored to the specific needs of your quarry, enhancing overall efficiency and productivity.

Key Features and Specifications of Crushing Equipment

When selecting crushing equipment, it’s important to consider several key features and specifications. Capacity is paramount; the equipment must be able to handle the quarry’s output demands. Zenith crushers are designed for high throughput, ensuring that your operation can process large volumes efficiently.

Durability is another critical factor. Quarry equipment faces harsh working conditions, and robust construction minimizes downtime and maintenance costs. Zenith’s crushers feature wear-resistant materials and advanced engineering to withstand the rigors of heavy use.

Energy efficiency is also a significant consideration. Modern quarries are increasingly environmentally conscious, and choosing energy-efficient machinery can reduce operational costs and carbon footprint. Zenith offers equipment with the latest technology to ensure energy efficiency without compromising performance.

Supporting Tools and Accessories for Optimal Performance

To enhance the functionality and efficiency of your crushing equipment, supporting tools and accessories are indispensable. Hydraulic rock breakers, for instance, are used to reduce oversized rocks that could block the crusher. Zenith’s rock breakers are known for their reliability and effectiveness.

Dust suppression systems are essential for maintaining air quality and compliance with environmental regulations. Zenith provides advanced dust control systems that can be integrated into existing equipment, ensuring a safer and cleaner work environment.

Lastly, maintenance tools such as crusher liners and wear parts are crucial for prolonging the life of the equipment. Zenith offers a range of customizable wear parts that are engineered for maximum durability and ease of replacement, reducing downtime and maintaining operational efficiency.

Equipping your crusher quarry with the right machinery, understanding the key features of your equipment, and utilizing essential supporting tools are fundamental steps to ensure your operation’s success. Zenith company is committed to providing high-quality, durable, and efficient solutions tailored to the needs of the quarry industry. With our comprehensive range of products and expertise, we are here to support your business every step of the way.